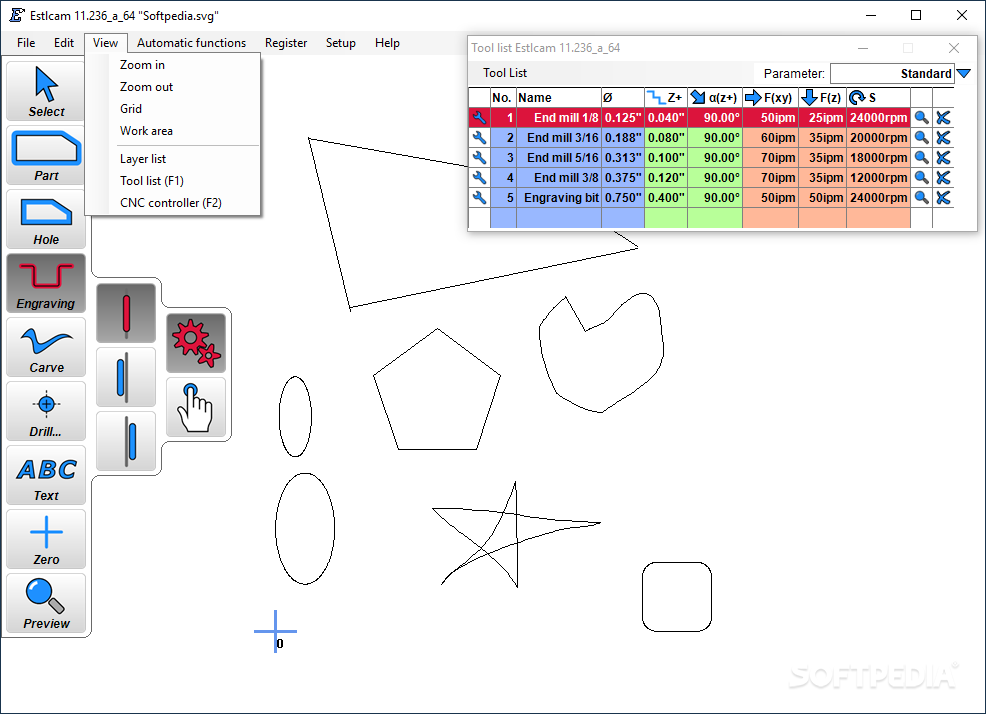

Last edit at 12:53PM by Roberts_Clif.Ĭomputer Programmer / Electronics Technician I have been looking at this Wirelessly Control a CNC from a Web Interface to finalize the MPCNC Electronics.Įdited 1 time(s). Have not actually cut anything Still procrastinating my final printing accessories Power Supply mounting, Ramps and LCD cases ect, though I made EstlCam G-Code for the MPCNC sketch Sena. I have been fumbling with learning to operate EstlCam through the minute delays before it will allow loading saved projects or slicing any G-Code for any project you are currently working on. I see you are using Slic3r to do some testing, what did you use to generate the Peace sign G-Code. The bolt heads were also to large and needed to have a little trimmed off on two bolts. If I had it to do over I would have used my bolt cutters then grinded the end smooth to allow the Nylock nuts too thread on. Like you purchased the 5/16 1-1/2 bolts I cut them close using a hacksaw the using a grinder to smooth the end an allow the Nylock nuts to thread on. I split my 3D Prints up with my two 3D Printers Being a low grade course threaded bolt made this somewhat easier. There is nothing I enjoy more than cuttingĭown bolts. There were no 5/16, 1-1/4" bolts so I had to cut down some 1-1/2" ones. Onto the engraving surface when there is no power to the Z motor.Ĭonduit wasn't a problem but the selection of hardware was severely limited.ĥ/16 Nylocks nuts are sold in packages of 15, Bolts are sold individually. One other problem I'm contending with is due to the weight of theĭewalt, the 4 start ACME screw won't hold it in place and it drops down The Dewalt tool holder from Thingiverse worksĮxceptionally well and is a great design. This thing really kicks up the dust so a vacuum hose attachment will be

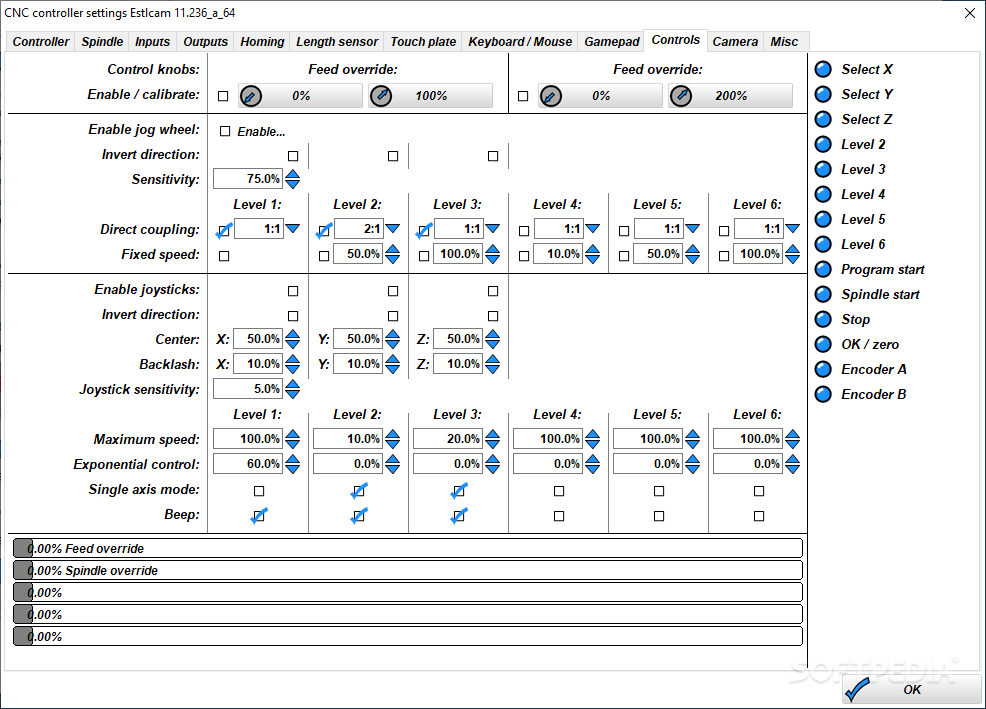

There any CNC firmware for the RAMPS 1.4? I'm going to look into a GRBL The only difference I could see was that there was a V1 splash screen setup. The V1 Engineering copy was any different from regular 3D printing firmware. I've heard of Marlin for CNC but I didn't see where I'm going to switch over the firmware from Marlin to something else. Both are very conservative values and the cut out tool The layer height (cutting depth) was set at 0.2mm with a feed rate of 60mm Which reduced most of the travel lines but I couldn't eliminate all of them. Generated gcode without breaking any bits.

I managed to engrave this 2 mm deep Peace symbol with some Slic3r Was looking forward to engraving some text. Either it was sent out from the manufacturer empty or

The package arrived but there were no contents in the Order for the Dewalt cut out tool I also ordered some 1/8"Įnd mills and V-bits. Guessing that wherever you park the tool is the origin The MPCNC design doesn't call out for end stops. I had to edit out the G28 home all axis command since I don't have any end Used Slic3r generated G-code to check all the movements and to plot a I couldn't get the pre-configured V1 Engineering Marlin 2.0 firmware toĬompile so I reverted back to a older version that I'm using for my printer. I added a Smart Controller in order to engrave directly from a SD card. The 72oz motors are hooked up to DRV8825's set in 1/16 step mode I'm using a Sainsmart RAMPS 1.4 shield with a Arduino 2560. Being a low grade course threaded bolt made this There were no 5/16, 1-1/4" bolts so I had to cut down someġ-1/2" ones. Conduit wasn't a problemīut the selection of hardware was severely limited.ĥ/16 Nylocks nuts are sold in packages of 15, Bolts are sold I made every effort to buy as many parts as I couldįrom a local DIY store. Motor mounts and DeWalt cut off tool holder were done in ABS and the To be consistent with the colors but I had aroundħ old partial spools of different colors and types to use up. This alsoĪccounted for the variety of filament colors. Than just one printer printing for 18 hours. I'd rather have a printer doing a 6 hour print The cable chain and Dewalt tool holder it has There is quite a bit of printing involved with making all of the parts. This thing is going to need a dedicated spot and I haven't quite figured I went with the more compact 24" x 24" version.

0 kommentar(er)

0 kommentar(er)